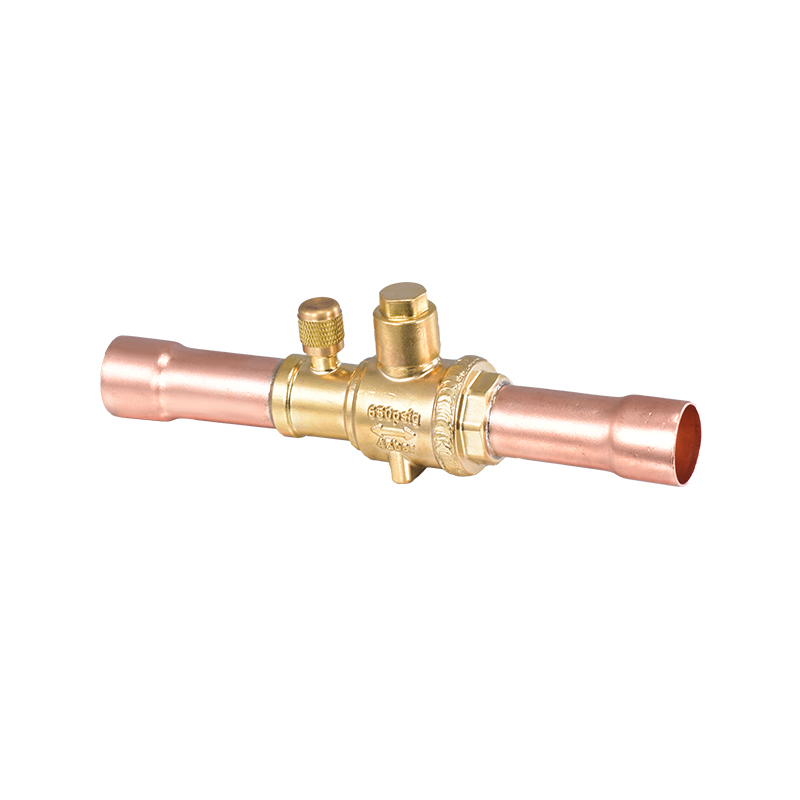

The Refrigeration Fitting Street Elbow Copper Press Tube is a specialized type of copper tube fitting used extensively in the HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industry. This fitting is engineered to provide a smooth transition for refrigerant lines, allowing for changes in direction without compromising the integrity of the system. The "Street Elbow" terminology refers to the fitting's use in applications where the tube is exposed or "on the street," meaning it's not hidden within walls or other structures.

Material and Construction

Copper is the material of choice for these fittings due to its good thermal conductivity, which is crucial for efficient heat exchange in refrigeration systems. Copper also offers high resistance to corrosion, which is essential in environments where the fittings may be exposed to moisture or aggressive chemicals. The press connection method used in these tubes ensures a secure and leak-free joint, which is critical in maintaining the efficiency and safety of the refrigeration system.

Advantages

1. Leak Resistance: The press connection provides a reliable seal, reducing the risk of refrigerant leaks that can harm the environment and compromise system performance.

2. Corrosion Resistance: Copper's natural resistance to corrosion means these fittings can withstand harsh conditions without deteriorating.

3. Durability: High-quality copper ensures that these fittings can withstand high pressures and temperatures, making them suitable for a wide range of applications.

4. Flexibility: The design of the street elbow allows for flexibility in installation, making it easier to navigate around obstacles and fit into tight spaces.

5. Efficiency: The smooth interior of the copper tube reduces friction, which helps maintain high flow rates and improves the overall efficiency of the refrigeration system.

Applications

1. Residential HVAC Systems: In homes, these fittings are used to connect the outdoor unit to the indoor units, ensuring a seamless flow of refrigerant.

2. Commercial Refrigeration: In supermarkets, restaurants, and other commercial settings, these fittings are critical for maintaining the cold chain in refrigeration and freezer units.

3. Industrial Applications: In industrial settings, such as cold storage facilities and manufacturing plants, these fittings help maintain precise temperature control.

4. Automotive Air Conditioning: In vehicles, these fittings are used in the air conditioning system to direct the flow of refrigerant.

Installation and Maintenance

1. Cleaning: Before installation, the tubes and fittings should be cleaned to remove any debris that could cause blockages or affect the seal.

2. Alignment: The tubes must be properly aligned to ensure a secure press connection and to avoid unnecessary stress on the fittings.

3. Pressing: The press connection should be made using the correct tools and following the manufacturer's specifications to ensure a secure and leak-free joint.

4. Leak Testing: After installation, the system should be leak tested to ensure that all connections are secure and there are no leaks.

5. Regular Maintenance: Regular inspection and maintenance of these fittings are essential to catch any potential issues early, such as corrosion or leaks, and to ensure the continued performance of the refrigeration system.

The Refrigeration Fitting Street Elbow Copper Press Tube is a vital component in the efficient operation of refrigeration and HVAC systems. Its durability, leak resistance, and flexibility make it a good choice for a wide range of applications. By understanding the importance of these fittings and following proper installation and maintenance practices, system operators can ensure the longevity and efficiency of their refrigeration systems.

English

English русский

русский Deutsch

Deutsch