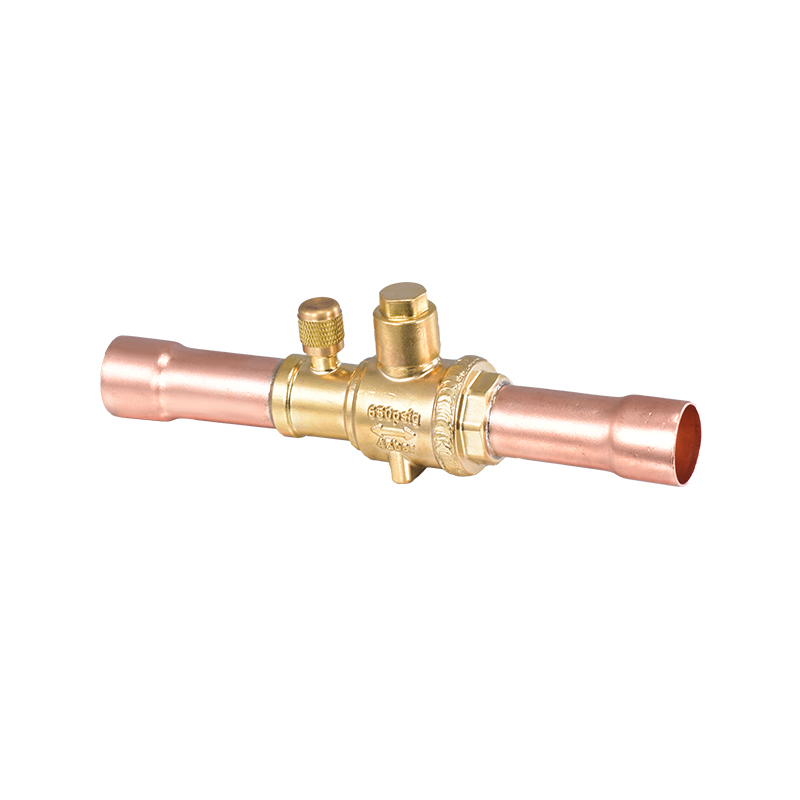

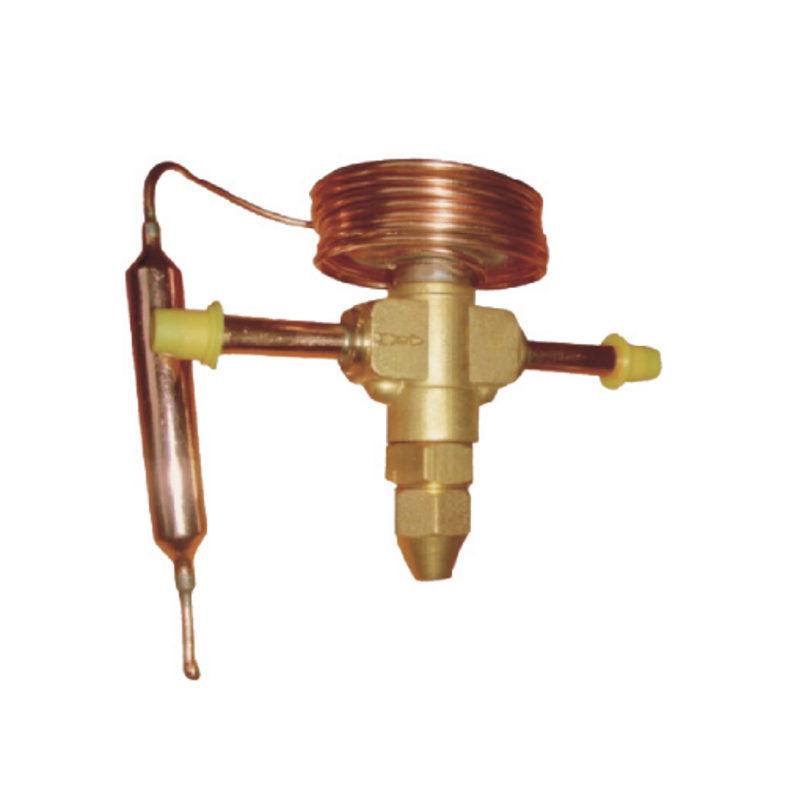

Threaded brass check valves are essential components in refrigeration systems, designed to regulate the flow of refrigerants and prevent backflow. These valves play a crucial role in maintaining the efficiency and safety of refrigeration units, ensuring that the system operates smoothly and effectively.

1. Material Quality:

Brass Construction: Threaded brass check valves are made from high-quality brass, which is known for its good corrosion resistance, especially in refrigeration systems where chemicals and moisture can be prevalent. This material choice ensures longevity and reduces the need for frequent replacements.

2. Threaded Connections:

Ease of Installation: Threaded connections on brass check valves allow for quick and easy installation. They can be screwed directly into pipe threads without the need for additional fittings, saving time and reducing the risk of leaks due to fewer connections.

3. Flow Control:

Unidirectional Flow: These valves are designed to allow fluid to flow in one direction only, preventing backflow, which is crucial in refrigeration systems to avoid contamination and to maintain the correct flow of refrigerant.

4. Pressure Handling:

High Pressure Ratings: Brass check valves can handle high pressure differentials without failure, making them suitable for a wide range of refrigeration applications, including those with high-pressure demands.

5. Temperature Tolerance:

Wide Temperature Range: Brass is capable of withstanding a broad range of temperatures, from sub-zero in cold storage to higher temperatures in some industrial refrigeration processes.

6. Noise Reduction:

Quiet Operation: Threaded brass check valves operate quietly, which is an important consideration in commercial and residential settings where noise pollution can be a concern.

7. Maintenance and Reliability:

Low Maintenance: Due to their simple design and robust construction, brass check valves require minimal maintenance, reducing downtime and maintenance costs.

Reliability: They are known for their reliability, ensuring that refrigeration systems operate without interruption, which is critical for maintaining the quality of perishable goods.

8. Compatibility:

Universal Fit: Threaded brass check valves are compatible with a wide range of pipe sizes and materials, making them a versatile choice for various refrigeration systems.

9. Cost-Effectiveness:

Affordability: Despite their high quality, brass check valves are relatively affordable, offering a cost-effective solution for refrigeration system upgrades or new installations.

10. Compliance with Standards:

Industry Standards: These valves are manufactured to comply with industry standards, ensuring that they meet the necessary safety and performance requirements.

11. Design Features:

Spring-Loaded Operation: Many threaded brass check valves feature a spring-loaded design that ensures a tight seal when the flow is reversed, preventing any backflow of refrigerant.

Non-Clogging Design: The design of these valves minimizes the risk of clogging, even in systems where there may be particulates in the refrigerant.

13. Environmental Considerations:

Recyclability: Brass is a recyclable material, contributing to the sustainability efforts of businesses that choose to use these valves in their refrigeration systems.

14. Aesthetic Appeal:

Attractive Finish: Brass valves have an attractive, polished finish that can complement the aesthetic of high-end refrigeration systems, especially in visible installations.

Threaded brass check valves are an essential component in the efficient and safe operation of refrigeration systems. Their durability, reliability, and ease of installation make them a popular choice for a wide range of applications. By ensuring a one-way flow of refrigerant and protecting against backflow, these valves help to maintain system efficiency, reduce the risk of damage, and prolong the life of the refrigeration system.

English

English русский

русский Deutsch

Deutsch