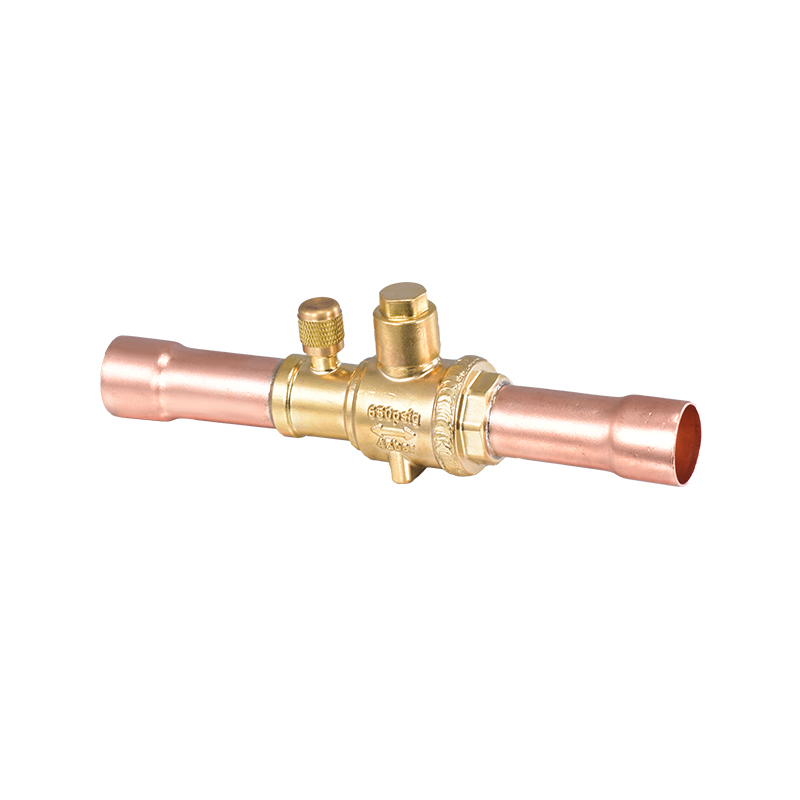

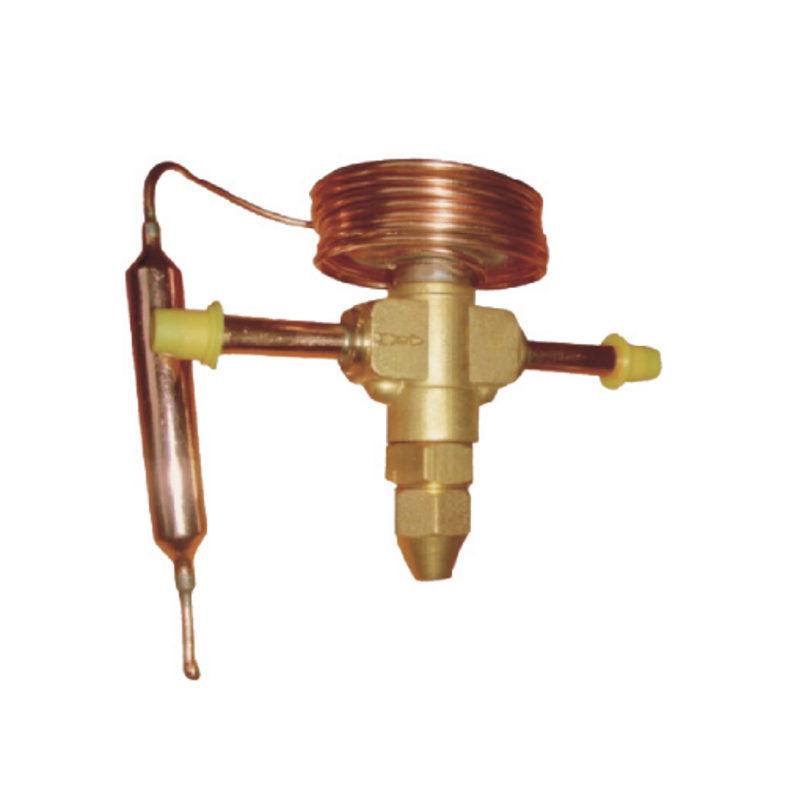

The Refrigeration System Elbow Copper Press Tube is a critical component in modern refrigeration and air conditioning systems. It is designed to facilitate the flow of refrigerants within these systems while allowing for changes in direction without significant pressure loss. Made from high-quality copper, these tubes are known for their durability, corrosion resistance, and high thermal conductivity, which are essential for maintaining the efficiency and longevity of refrigeration systems.

Design and Function

The design of the Refrigeration System Elbow Copper Press Tube is centered around its ability to change the direction of the refrigerant flow within a system. The "elbow" in its name refers to the 45-degree bend that the tube makes, allowing the refrigerant to turn a corner without the need for additional fittings. This design is crucial for compact and efficient system layouts, particularly in spaces where traditional pipe bending would be impractical or space-consuming.

Material Properties

Copper is the material of choice for these tubes due to several inherent properties that make it ideal for refrigeration applications:

1. Corrosion Resistance: Copper is highly resistant to corrosion, which means it can withstand the harsh conditions often found in refrigeration systems without degrading over time.

2. Thermal Conductivity: Copper's high thermal conductivity allows it to efficiently transfer heat, which is crucial for maintaining the temperature balance within a refrigeration system.

3. Durability: Copper is a strong and durable material that can withstand high pressures and temperatures, making it suitable for the demanding conditions of refrigeration systems.

4. Toxicity: Copper is non-toxic, which is an important consideration when dealing with refrigerants that can be harmful to the environment and human health.

Applications

Refrigeration System Elbow Copper Press Tubes are used in a wide range of applications, including:

1. Residential and Commercial Air Conditioning: In both residential and commercial settings, these tubes are used to direct the flow of refrigerant in air conditioning units, ensuring efficient cooling.

2. Industrial Refrigeration: In industrial settings, where large-scale cooling is required, these tubes are essential for maintaining the flow of refrigerants in complex systems.

3. Automotive Air Conditioning: In vehicles, these tubes are used to direct the flow of refrigerant in the car's air conditioning system, providing comfort to passengers.

4. Supermarket and Retail Display Cases: In refrigerated display cases, these tubes help maintain the cold chain, ensuring the freshness of perishable goods.

Installation and Maintenance

The installation of Refrigeration System Elbow Copper Press Tubes is typically straightforward due to the use of press fittings. These fittings allow for quick and easy connections without the need for specialized tools or skills. However, it is crucial to ensure that the fittings are properly crimped to avoid leaks and maintain the integrity of the system.

Maintenance of these tubes involves regular inspections to check for signs of wear, corrosion, or leaks. Since copper is a relatively inert material, maintenance is generally minimal, but it is still essential to catch any issues early to prevent system failures.

The Refrigeration System Elbow Copper Press Tube is a vital component in the efficient operation of refrigeration and air conditioning systems. Its design, material properties, and applications make it an indispensable part of modern cooling technology. By understanding the role and importance of these tubes, technicians and engineers can ensure the good performance and longevity of their refrigeration systems.

English

English русский

русский Deutsch

Deutsch