In the intricate world of refrigeration systems, the refrigerant hand valve plays a crucial role in the circulation and control of refrigerants. This manual control device is essential for the safe and efficient operation of various cooling applications, from residential air conditioning units to large-scale industrial refrigeration systems. The Refrigerant Hand Valve for Refrigeration is designed to provide precise control over the flow of refrigerants, ensuring good performance and safety.

1. Function and Importance

System Charging: When a refrigeration system is being charged with refrigerant, the hand valve can be used to regulate the flow, preventing overcharging and ensuring the correct amount of refrigerant is added.

Maintenance and Repair: During maintenance or repair, the hand valve can be closed to isolate a section of the system, allowing work to be done safely without the risk of refrigerant leakage.

System Balancing: In systems with multiple circuits or components, the hand valve can be used to balance the flow of refrigerant, ensuring even cooling and preventing hotspots or inefficiencies.

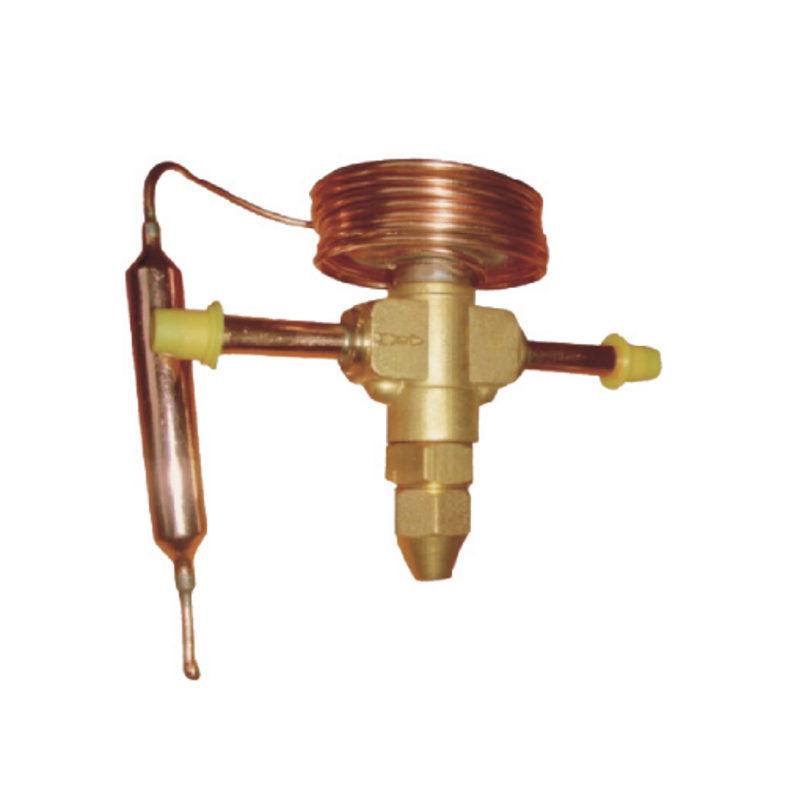

2. Design and Construction

Valve Body: The body of the hand valve is designed to withstand high pressures and is often reinforced with additional support structures.

Stem and Seat: The stem is the part of the valve that is turned to open or close the valve. It is typically made from stainless steel to resist wear and corrosion. The seat is the surface against which the stem seals when the valve is closed, and it is often made from a soft material like Teflon to ensure a good seal.

Gaskets and Seals: High-quality gaskets and seals are used throughout the valve to prevent refrigerant leaks and ensure a long service life.

4. Installation and Operation

Proper installation and operation of a refrigerant hand valve are crucial for its effectiveness and longevity. Technicians must ensure that the valve is installed in the correct orientation and that it is compatible with the refrigerant being used. The valve should be opened and closed slowly to avoid damage to the seals and to prevent sudden pressure changes in the system.

5. Maintenance and Safety

Regular maintenance is essential to keep a refrigerant hand valve in good working order. This includes checking for leaks, ensuring that the valve operates smoothly, and replacing any worn or damaged parts. Safety is also a important concern when working with refrigerant hand valves. Technicians must use appropriate personal protective equipment and follow safety procedures to prevent exposure to refrigerants, which can be harmful or even lethal.

6. Applications

Residential and Commercial Air Conditioning: To control the flow of refrigerant in split systems, window units, and central air conditioning systems.

Industrial Refrigeration: In large-scale cooling systems used in food processing, cold storage, and manufacturing facilities.

Automotive Air Conditioning: To control the flow of refrigerant in vehicle air conditioning systems.

Heat Pumps: In both residential and commercial heat pump systems to control the flow of refrigerant during heating and cooling cycles.

In conclusion, the Refrigerant Hand Valve for Refrigeration is a critical component in the safe and efficient operation of refrigeration systems. Its design, construction, and operation must be carefully considered to ensure that it performs its function reliably and safely. With proper installation, maintenance, and use, a refrigerant hand valve can contribute significantly to the longevity and performance of any refrigeration system.

English

English русский

русский Deutsch

Deutsch