In the realm of cold storage facilities, maintaining a safe and efficient environment is of very importance. The Cold Storage Brass Safety Valve plays a pivotal role in ensuring the safety and reliability of these critical systems. Designed to prevent overpressure and maintain system integrity, this valve is an essential component in the refrigeration and HVAC industry.

1. Overview of the Cold Storage Brass Safety Valve

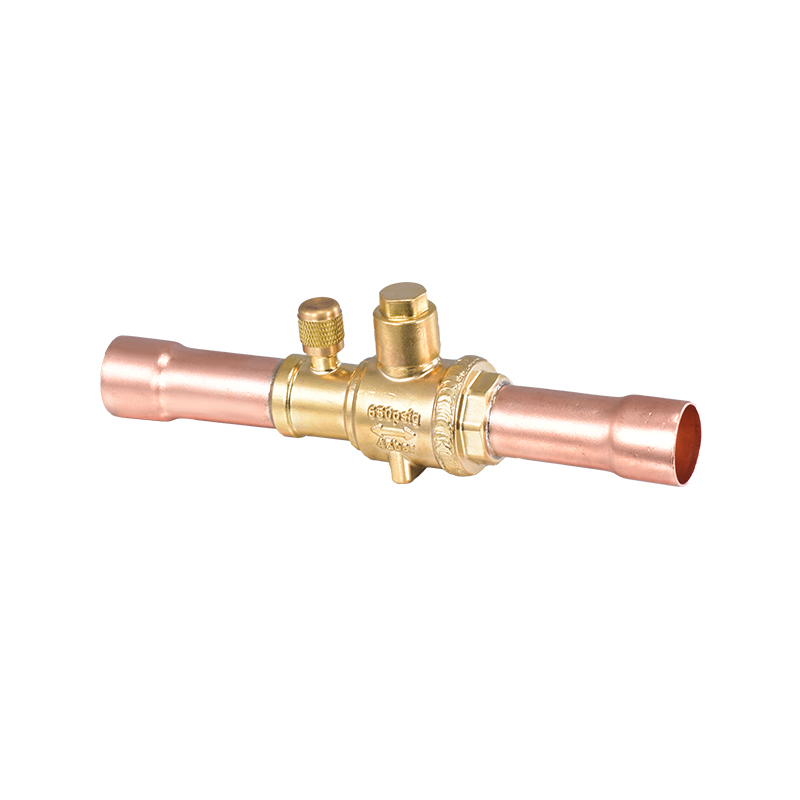

The Cold Storage Brass Safety Valve is a type of pressure relief valve specifically engineered for use in cold storage environments. It is designed to automatically release excess pressure from a refrigeration system when the pressure exceeds a predetermined level, thus protecting the system from damage and preventing potential hazards. Made from high-quality brass, these valves are known for their durability, corrosion resistance, and ability to withstand the harsh conditions often found in cold storage facilities.

2. Key Features and Benefits

Material and Construction: The valve is constructed from brass, a material chosen for its strength, durability, and resistance to corrosion. Brass is also non-magnetic and has good thermal conductivity, which is beneficial in maintaining consistent temperatures within the cold storage environment.

Precision Engineering: The Cold Storage Brass Safety Valve is engineered with precision to ensure accurate pressure relief. It is designed to open at a specific pressure setting, allowing excess pressure to escape and then reseal once the pressure returns to a safe level.

Reliability and Durability: Due to the use of brass and advanced manufacturing techniques, these valves are built to last. They can withstand the rigors of continuous operation in cold storage facilities without compromising their performance.

Easy Maintenance: The design of the valve allows for easy maintenance and inspection. It can be disassembled and cleaned without the need for specialized tools, making it a practical choice for facilities with limited maintenance resources.

3. Applications

Industrial Cold Storage Facilities: These valves are crucial in large-scale cold storage facilities where the risk of overpressure is high due to the extensive use of refrigeration systems.

Commercial Refrigeration: In supermarkets, restaurants, and other commercial settings, these valves help maintain the integrity of refrigeration systems that store perishable goods.

Pharmaceutical Storage: For the storage of temperature-sensitive pharmaceuticals, the Cold Storage Brass Safety Valve ensures that the refrigeration system operates within safe pressure limits.

4. Installation and Operation

The installation of a Cold Storage Brass Safety Valve should be carried out by trained professionals to ensure that it is correctly positioned and set to the appropriate pressure. The valve should be installed in a location that is easily accessible for regular inspections and maintenance. During operation, the valve remains closed until the pressure within the system reaches the set level, at which point it opens to release pressure, preventing damage to the system and ensuring the safety of the facility.

The Cold Storage Brass Safety Valve is a critical component in the safe and efficient operation of refrigeration systems in cold storage facilities. Its robust construction, precision engineering, and adjustable pressure settings make it a good choice for a wide range of applications. By ensuring that pressure within the system remains within safe limits, these valves help to protect both the integrity of the refrigeration system and the safety of the facility and its occupants.

English

English русский

русский Deutsch

Deutsch