In the intricate world of refrigeration systems, the General Elbow Rotalock Fitting Valve stands as a critical component that ensures the seamless integration and operation of various system parts. This valve is designed to provide a secure and leak-free connection between refrigeration lines, ensuring the efficient transfer of refrigerants without interruption. The Rotalock fitting is particularly known for its ease of installation and its ability to maintain a tight seal even under fluctuating pressures and temperatures.

1. Design and Construction

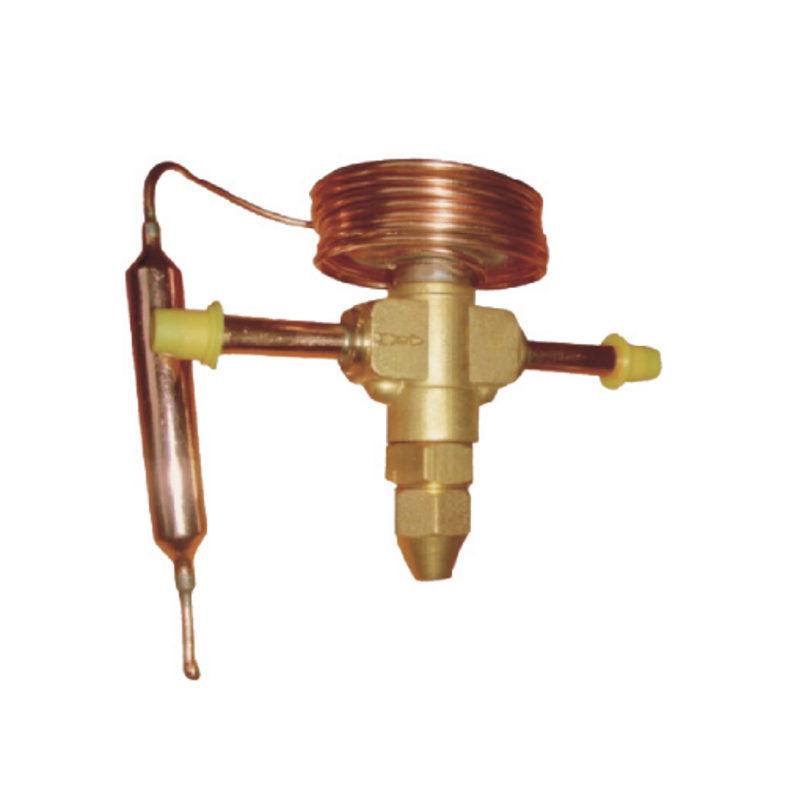

The General Elbow Rotalock Fitting Valve is constructed with precision to meet the demands of high-pressure refrigeration systems. It typically features a robust body made from brass which are chosen for their durability and resistance to corrosion.

2. Operation and Benefits

The operation of the General Elbow Rotalock Fitting Valve is straightforward. It is installed by threading the pipe into the fitting until it bottoms out, then tightening the locking ring with a wrench. The unique Rotalock design allows for a quarter turn to lock the fitting in place, providing a secure connection that can withstand the rigors of a refrigeration system.

Some of the key benefits of using this type of valve include:

Leak Prevention: The Rotalock mechanism provides a reliable seal, reducing the risk of refrigerant leaks that can lead to system inefficiencies and environmental concerns.

Ease of Installation: The quarter-turn locking system simplifies the installation process, reducing the time and effort required to connect refrigeration lines.

Versatility: The valve is compatible with a variety of pipe materials, including copper, steel, and plastic, making it a versatile choice for different types of refrigeration systems.

Durability: The high-quality materials used in the construction of the valve ensure that it can withstand the pressures and temperatures typical of refrigeration systems without failing.

3. Applications

Residential and Commercial Air Conditioning: Where the valve is used to connect outdoor and indoor units, ensuring a secure and leak-free connection.

Industrial Refrigeration: In large-scale systems where the valve's ability to handle high pressures and temperatures is crucial.

Supermarket and Retail Display Cases: Where the valve's durability and leak prevention are essential to maintain the integrity of the refrigeration system.

HVAC Systems: In heating, ventilation, and air conditioning systems where the valve's ability to change direction is beneficial for routing lines.

4. Maintenance and Troubleshooting

Proper maintenance of the General Elbow Rotalock Fitting Valve is essential to ensure its longevity and performance. Regular inspections should be conducted to check for any signs of wear or damage to the sealing element or the locking ring. If a leak is detected, it is often a sign that the sealing element needs to be replaced or that the fitting needs to be re-tightened.

In the event of a leak, the valve can be easily disassembled for repair or replacement of the sealing element. This feature makes the valve a cost-effective choice, as it can be serviced without the need for complete replacement.

The General Elbow Rotalock Fitting Valve for Refrigeration is a critical component in the field of refrigeration and air conditioning. Its design, construction, and operation contribute to the efficiency and reliability of these systems. By providing a secure connection and leak-free operation, this valve helps to maintain the integrity of the refrigeration system, ensuring good performance and longevity. As a result, it is a valuable investment for any application that requires the transfer of refrigerants under pressure.

English

English русский

русский Deutsch

Deutsch