In semiconductor temperature control systems, the precision and stability of thermal regulation are critical to ensuring product yield and process consistency. The Semiconductor Temperature Control Three-Way Tube Fitting is a high-performance refrigeration component engineered to meet the demanding requirements of modern semiconductor equipment.

This Three-Way Tube Fitting combines reliable sealing performance, corrosion resistance, and compact design, making it ideal for applications requiring high-precision cooling and heating control.

Design and Construction

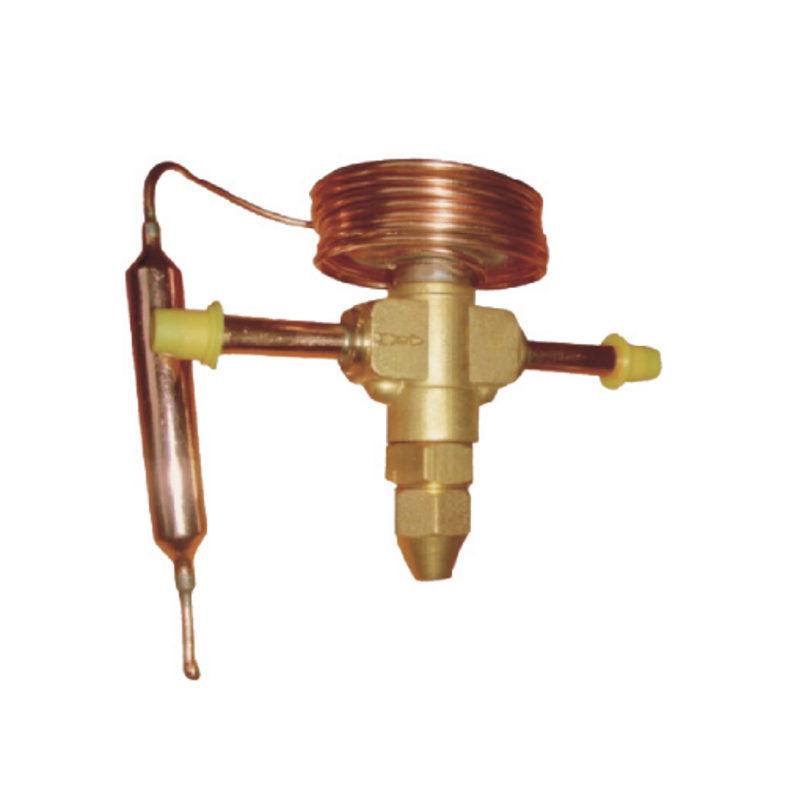

The Semiconductor Temperature Control Three-Way Tube Fitting is precisely machined from high-grade brass or nickel-plated brass, ensuring both mechanical strength and long-term resistance to corrosion.

Its compact right-angle structure and precision-threaded fittings provide a secure, leak-free connection in temperature control loops.

This design is especially suited for semiconductor applications where the Three-Way Tube Fitting must withstand continuous operation, clean-room environments, and contact with heat transfer fluids such as deionized water, glycol, or cooling oils.

Three-Way Connector Function

A key feature of this Three-Way Tube Fitting is its three-way flow design, which allows the user to distribute or combine the flow of coolant between two circuits.

Depending on system configuration, it can act as a mixing Three-Way Tube Fitting (two inlets, one outlet) or a diverting Three-Way Tube Fitting (one inlet, two outlets), providing flexibility for both heating and cooling control.

The precision-machined internal passages minimize flow restriction and pressure loss, improving overall thermal system efficiency.

Operational Efficiency

The Three-Way Tube Fitting’s smooth internal surface and optimized geometry ensure low flow resistance and stable temperature control during rapid load changes.

Its robust mechanical construction enables reliable operation under high-frequency switching conditions without leakage.

Thanks to its high sealing integrity and precision threads, maintenance intervals are significantly reduced compared to conventional connectors.

Applications

The Semiconductor Temperature Control Three-Way Tube Fitting is designed for high-precision temperature management in advanced semiconductor and related industries.

It is commonly used in:

Semiconductor Processing Equipment: TCU (Temperature Control Units), chillers, and thermal plates for wafer processing.

Laser and Optics Cooling: Maintaining stable optical module or laser head temperature.

Precision Instruments: Analytical or inspection tools requiring strict temperature uniformity.

Chemical and Pharmaceutical Systems: Equipment involving heat transfer fluids and closed-loop cooling control.

Maintenance and Durability

The Three-Way Tube Fitting’s modular structure allows for easy installation, disassembly, and replacement.

Its metal-sealed design prevents leakage and contamination, ensuring long service life even under demanding clean-room or high-temperature conditions.

Surface treatments such as nickel plating further enhance corrosion resistance and surface cleanliness.

Safety and Compliance

Designed in accordance with industrial refrigeration and semiconductor equipment standards, this Three-Way Tube Fitting meets or exceeds performance requirements for pressure, temperature, and material compatibility.

Its robust construction ensures reliable sealing performance and consistent operation, providing users with confidence in both system safety and process stability.

Key Features

High-precision brass or nickel-plated brass construction

Excellent corrosion and leak resistance

Compact, clean-room compatible design

Low pressure drop and high thermal efficiency

Configurable for mixing or diverting flow

Long service life and easy maintenance

English

English русский

русский Deutsch

Deutsch