In the field of refrigeration, the choice of valves can significantly impact the efficiency, safety, and longevity of the entire system. British Tees Valves have established a reputation for their outstanding performance and reliability in various industrial applications, including refrigeration.

1. High-Quality Materials and Construction

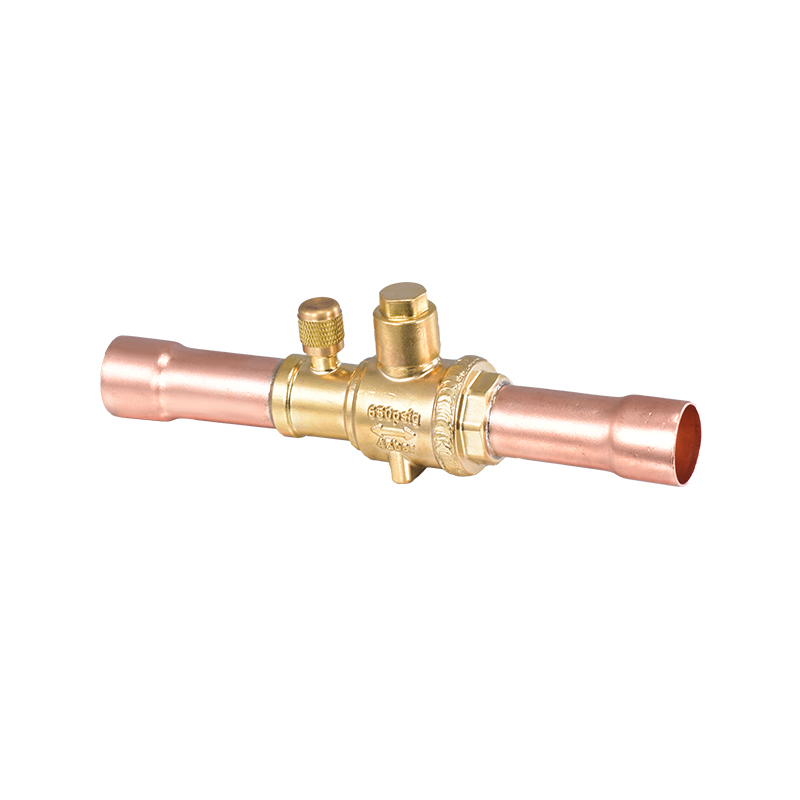

British Tees Valves are known for their robust construction and use of high-quality materials. They are typically made from materials such as stainless steel, which is resistant to corrosion and can withstand the harsh conditions often found in refrigeration systems. This ensures that the valves maintain their integrity over time, reducing the need for frequent replacements and minimizing downtime.

2. Precision Engineering

The precision engineering of British Tees Valves ensures that they offer a high degree of accuracy in controlling the flow of refrigerants. This precision is crucial in maintaining the correct pressure and temperature within the system, which in turn optimizes energy efficiency and prevents the system from working harder than necessary.

3. Durability and Longevity

Due to their sturdy construction and the use of durable materials, British Tees Valves are designed to last. They can withstand the wear and tear of continuous operation and the corrosive nature of some refrigerants, which means they require less frequent maintenance and replacement. This durability translates into cost savings for businesses over the long term.

4. Wide Range of Sizes and Configurations

British Tees Valves offer a wide range of sizes and configurations to suit various refrigeration system requirements. Whether it's a small domestic system or a large industrial setup, there is a British Tees Valve that can fit the need. This versatility allows for greater flexibility in system design and ensures that the valve can be tailored to the specific requirements of the application.

5. Ease of Installation and Maintenance

British Tees Valves are designed with ease of installation and maintenance in mind. Their compact design and straightforward operation make them easy to install and service, reducing the need for specialized tools and expertise. This not only speeds up the installation process but also simplifies maintenance, reducing overall operational costs.

6. Compliance with Industry Standards

British Tees Valves are manufactured to comply with international industry standards, ensuring that they meet the high levels of safety and performance. This compliance gives users confidence in the quality and reliability of the valves, knowing that they have been rigorously tested and certified to perform under various conditions.

7. outstanding Sealing Performance

One of the critical aspects of any valve in a refrigeration system is its sealing performance. British Tees Valves are designed with advanced sealing mechanisms that prevent leaks and ensure that the refrigerant remains contained within the system. This not only maintains the efficiency of the system but also helps to prevent environmental damage caused by refrigerant leaks.

8. Noise Reduction

Refrigeration systems can sometimes be noisy, especially in commercial settings where noise can be a distraction or a nuisance. British Tees Valves are designed to minimize noise during operation, contributing to a quieter environment and improving the overall user experience.

In conclusion, British Tees Valves for refrigeration systems offer a combination of high-quality materials, precision engineering, durability, versatility, ease of use, compliance with standards, outstanding sealing, noise reduction, customization options, and global support. These advantages and selling points make them a top choice for professionals in the refrigeration industry who demand the nice for their systems.

English

English русский

русский Deutsch

Deutsch