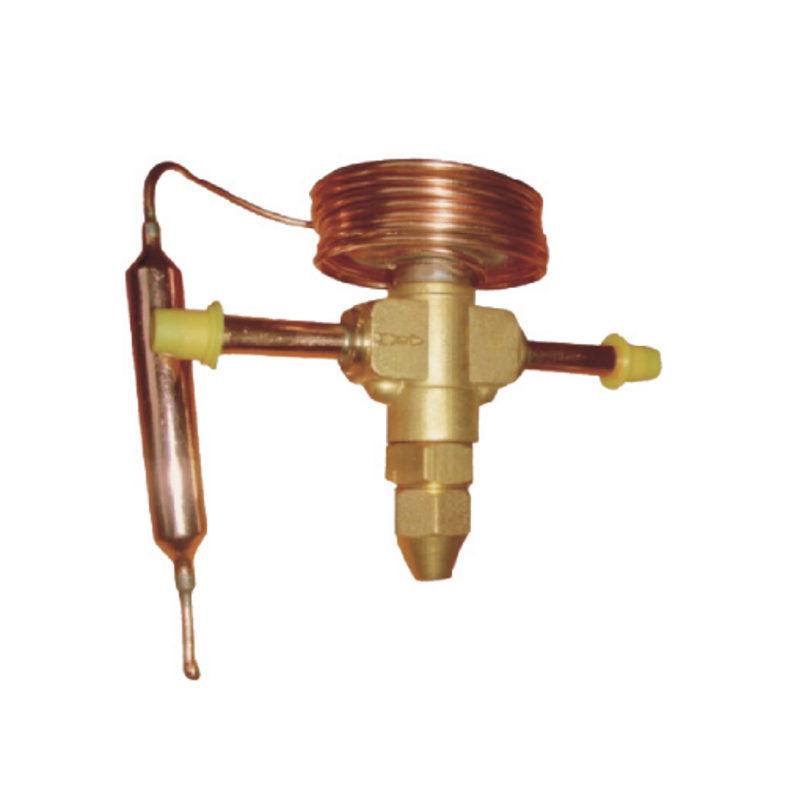

In the realm of heating, ventilation, and air conditioning (HVAC) systems, the Compressor Refrigeration Cast Iron Shut-Off Vale plays a pivotal role. These valves are integral to the proper functioning of refrigeration and air conditioning units, ensuring the efficient circulation of refrigerants and maintaining system integrity.

Overview of Compressor Refrigeration Cast Iron Shut-Off Valves

Compressor refrigeration cast iron shut-off valves are designed to control the flow of refrigerant in a closed-loop system. They are

installed in the suction and discharge lines of a compressor, allowing for the regulation of pressure and flow. Made from cast iron, these valves are known for their durability and resistance to corrosion, which is crucial in environments where moisture and chemicals are present.

Key Features

1. Durability: Cast iron is chosen for its strength and ability to withstand high pressures. This material is less prone to cracking or breaking under stress, which is essential in a system where high pressures are common.

2. Corrosion Resistance: The nature of cast iron provides a natural barrier against corrosion, which is particularly important in refrigeration systems where chemicals like refrigerants can be corrosive.

3. Leak-Proof Design: Shut-off valves are designed to create a tight seal when closed, preventing any leaks that could lead to refrigerant loss and system inefficiency.

4. Ease of Operation: These valves are typically equipped with manual or automatic actuators that allow for easy operation and control.

Types of Compressor Refrigeration Cast Iron Shut-Off Valves

1. Ball Valves: These valves use a ball with a hole through it to control the flow. When the ball is turned 90 degrees, the hole aligns with the flow path, allowing fluid to pass through.

2. Globe Valves: These valves control flow using a circular disk that, when rotated, opens or closes a passage through which the fluid can flow.

3. Gate Valves: These are characterized by a sliding gate that moves in a straight path perpendicular to the flow. When the gate is fully open, it is completely out of the flow path, which minimizes resistance to flow.

4. Check Valves: These are automatic valves that allow fluid to flow in only one direction, preventing backflow.

Applications

1. Residential HVAC Systems: In homes, these valves help regulate the flow of refrigerant in air conditioning units and heat pumps.

2. Commercial Refrigeration: In supermarkets and other commercial settings, these valves are crucial for maintaining the temperature of refrigerated display cases and walk-in coolers.

3. Industrial Processes: In industrial settings, where precise temperature control is necessary for processes like food processing or chemical manufacturing, these valves ensure the efficient operation of cooling systems.

Maintenance and Troubleshooting

Proper maintenance of compressor refrigeration cast iron shut-off valves is essential for their longevity and performance. Regular checks for leaks, corrosion, and proper operation are recommended. If a valve is not sealing properly or is difficult to operate, it may need to be replaced or repaired.

In summary, compressor refrigeration cast iron shut-off valves are critical components in the operation of HVAC systems. They ensure the efficient flow of refrigerants, maintain system pressure, and contribute to the overall reliability and longevity of the equipment. By understanding their function, features, and proper maintenance, facility managers and HVAC technicians can ensure that these valves continue to perform their essential role in maintaining comfortable and controlled environments.

English

English русский

русский Deutsch

Deutsch