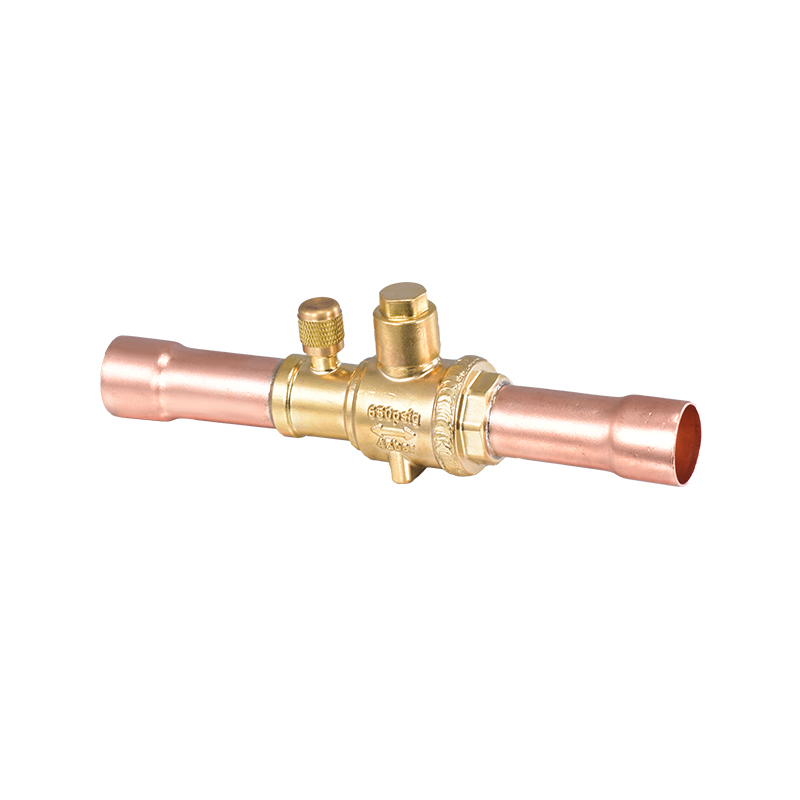

In the realm of refrigeration systems, the compressor plays a pivotal role in maintaining the desired temperature and pressure levels. The discharge valve, in particular, is a critical component that controls the flow of refrigerant from the compressor to the condenser. The Refrigeration Compressor Discharge Rotalock Valve, with its unique design and features, offers several advantages that enhance the performance and reliability of refrigeration systems.

1. Leak-Free Sealing

One of the primary advantages of the rotalock valve is its leak-free sealing mechanism. The rotalock design ensures a secure connection between the valve and the refrigeration system, reducing the risk of refrigerant leaks. This is crucial for maintaining system efficiency and preventing environmental damage caused by refrigerant emissions.

2. Ease of Installation

The rotalock valve simplifies the installation process. Its unique design allows for quick and easy connection without the need for special tools or complex procedures. This not only saves time but also reduces the likelihood of installation errors, which can lead to system failures.

3. Durability and Longevity

High-quality materials and robust construction make the rotalock valve highly durable. It is designed to withstand the pressures and temperatures typical in refrigeration systems, ensuring a long service life with minimal maintenance.

4. Compatibility

The rotalock valve is compatible with a wide range of refrigeration systems, making it a versatile choice for various applications. Its universal design allows for easy integration with different types of compressors and refrigeration circuits.

5. Pressure Control

The valve's design allows for precise control of pressure, which is essential for the efficient operation of the compressor. By regulating the flow of refrigerant, the rotalock valve helps to prevent pressure surges that can damage the compressor or other components.

6. Corrosion Resistance

The rotalock valve is made from materials that are resistant to corrosion, which is particularly important in environments where the refrigerant or other system fluids may be corrosive. This resistance extends the valve's lifespan and reduces the need for frequent replacements.

7. Noise Reduction

The operation of the rotalock valve is designed to minimize noise, which is a common issue with some types of valves. This makes it a good choice for applications where noise reduction is a priority, such as in residential or commercial settings.

8. Energy Efficiency

By ensuring a smooth and controlled flow of refrigerant, the rotalock valve contributes to the overall energy efficiency of the refrigeration system. It helps to reduce energy consumption by preventing pressure losses that can occur with less efficient valves.

9. Safety Features

The rotalock valve often includes safety features such as pressure relief mechanisms, which can protect the system from over-pressurization. This not only safeguards the equipment but also ensures the safety of personnel working with the system.

10. Cost-Effectiveness

While the initial cost of a rotalock valve may be higher than that of some other types of valves, its long-term cost-effectiveness is significant. The reduced need for maintenance and replacement, along with its energy-saving capabilities, can result in substantial savings over time.

In summary, the Refrigeration Compressor Discharge Rotalock Valve is an essential component in the efficient operation of refrigeration systems. Its design and construction offer a range of benefits that contribute to the reliability, safety, and cost-effectiveness of these systems. By choosing a Rotalock Valve, businesses can ensure that their refrigeration systems are equipped to handle the demands of their operations with minimal risk of failure or downtime.

English

English русский

русский Deutsch

Deutsch