In the intricate world of refrigeration systems, the efficiency and reliability of the components used are crucial for maintaining good performance. One such component that plays a vital role is the Refrigeration Forged Compressor Tees One-Way Valve. This specialized valve is engineered to ensure the unidirectional flow of refrigerants, preventing backflow and ensuring that the system operates smoothly and safely.

1. Precision Engineering and Durability

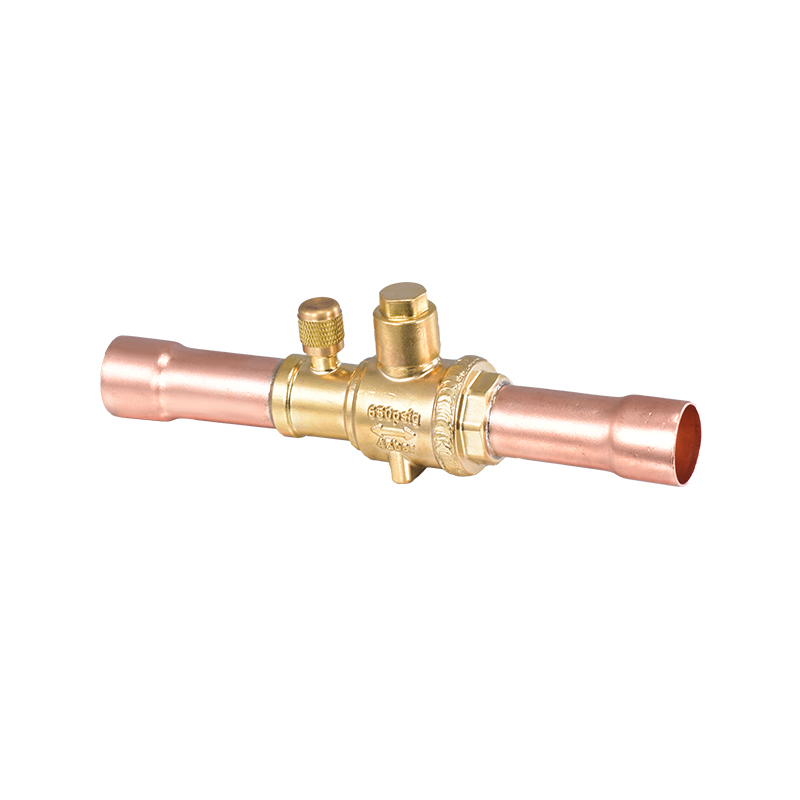

Refrigeration Forged Compressor Tees One-Way Valves are precision-engineered to withstand the rigors of continuous operation in demanding environments. The forged construction provides outstanding strength and durability, ensuring that the valve can handle high pressures and temperatures without failure. This robustness is crucial for maintaining the integrity of the refrigeration system and reducing the need for frequent replacements or repairs.

2. Enhanced System Efficiency

The one-way valve's primary function is to prevent the backflow of refrigerant, which can lead to inefficiencies and potential damage to the compressor. By ensuring that the refrigerant flows in the correct direction, these valves help to maintain the system's efficiency, reducing energy consumption and operational costs. This is particularly important in large-scale commercial refrigeration systems where energy efficiency can have a significant impact on the bottom line.

3. Easy Integration and Compatibility

Refrigeration systems are often complex, with numerous components that need to work together seamlessly. The Refrigeration Forged Compressor Tees One-Way Valve is designed to be easily integrated into existing systems, ensuring compatibility with a wide range of compressors and other system components. This ease of integration simplifies maintenance and upgrade processes, reducing downtime and associated costs.

4. outstanding Material Quality

The choice of materials for these valves is critical to their performance and longevity. High-quality brass are often used in the construction of these valves, providing resistance to corrosion and ensuring that the valve remains functional even in the presence of aggressive refrigerants. This material quality also contributes to the valve's ability to withstand the wear and tear of long-term use.

5. Precise Flow Control

The Refrigeration Forged Compressor Tees One-Way Valve offers precise control over the flow of refrigerant, which is essential for maintaining the desired temperature within the system. The valve's design ensures that it opens and closes smoothly, providing a consistent flow rate and preventing any fluctuations that could impact the system's performance.

6. Noise Reduction

In many commercial settings, noise pollution is a concern. The operation of refrigeration systems can sometimes contribute to this issue. The design of the Refrigeration Forged Compressor Tees One-Way Valve helps to minimize noise during operation, making it a more environmentally friendly option for noise-sensitive areas.

7. Safety Features

Safety is a important concern in any industrial setting. These valves are designed with safety in mind, with features such as leak-proof seals and pressure relief mechanisms to prevent accidents and ensure the safety of personnel working near the system. The one-way operation also helps to prevent the dangerous buildup of pressure that can occur with backflow.

In conclusion, the Refrigeration Forged Compressor Tees One-Way Valve is a critical component in the efficient operation of refrigeration systems. Its precision engineering, durability, compatibility, and safety features make it an essential choice for maintaining the performance and reliability of these systems. By choosing a high-quality one-way valve, businesses can ensure that their refrigeration systems operate at peak efficiency, reducing costs and extending the life of the equipment.

English

English русский

русский Deutsch

Deutsch