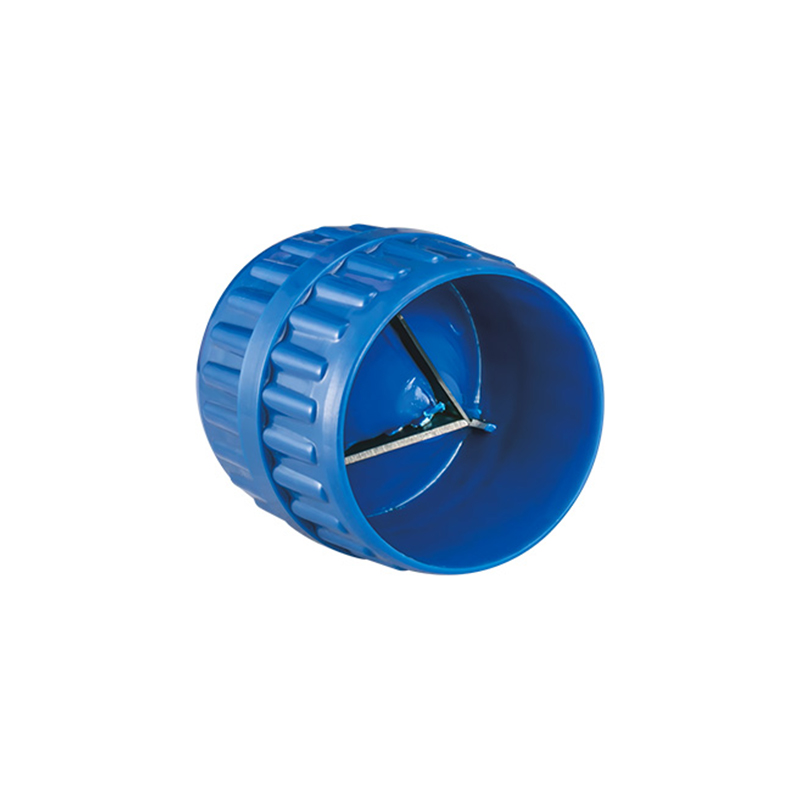

The Inner-Outer Manual Reaming Deburring Apparatus is a specialized tool designed to address the challenges of deburring and reaming in a variety of applications. This apparatus stands out for its ability to handle both internal and external deburring tasks with precision and ease. It is an essential tool for industries such as automotive, aerospace, metalworking, and general manufacturing where smooth, burr-free surfaces are critical.

1. Versatile Functionality

The Inner-Outer Manual Reaming Deburring Apparatus is designed to handle a wide range of deburring tasks, both internally and externally. This versatility means that users can tackle different types of materials and shapes without needing to switch tools, saving time and resources.

2. Manual Operation for Precision Control

Manual operation allows for greater control over the deburring process, ensuring that the user can apply the exact amount of pressure needed for the job. This precision control is particularly important in applications where over-deburring can lead to material weakening or damage.

3. Durable Construction

Made from high-quality materials, the Inner-Outer Manual Reaming Deburring Apparatus is built to last. Its durability ensures that it can withstand the rigors of regular use without compromising on performance or integrity.

4. Ease of Use

The apparatus is designed with user-friendliness in mind. Its intuitive design allows for quick setup and easy operation, even for those who are not experts in deburring. This ease of use reduces the learning curve and increases productivity.

5. Cost-Effective Solution

Compared to automated deburring machines, the Inner-Outer Manual Reaming Deburring Apparatus offers a more cost-effective solution for small to medium-sized operations or for businesses that do not require high-volume deburring.

6. Portability

The compact and lightweight design of the apparatus makes it highly portable, allowing users to take it to the work site or move it between workstations with ease. This portability is particularly beneficial in workshops with limited space or in field operations.

7. Customization and Adaptability

The Inner-Outer Manual Reaming Deburring Apparatus can be customized with different attachments and accessories to suit specific deburring needs. This adaptability ensures that the tool remains relevant and useful as deburring requirements change.

8. Improved Surface Finish

The precision of the deburring process provided by this apparatus results in a outstanding surface finish. Smooth, burr-free surfaces are essential in applications where fit and function are critical, such as in the assembly of precision machinery or the manufacturing of aircraft components.

9. Safety Features

Safety is a important consideration in any workshop tool. The Inner-Outer Manual Reaming Deburring Apparatus includes features designed to minimize the risk of injury, such as ergonomic handles and secure locking mechanisms to prevent accidental movement during operation.

10. Longevity and Low Maintenance

The tool's robust construction and high-quality components mean that it requires minimal maintenance, reducing downtime and maintenance costs. Its longevity ensures that it remains a valuable asset in the workshop for years to come.

11. Environmental Considerations

In industries where sustainability is a priority, the Inner-Outer Manual Reaming Deburring Apparatus can contribute to greener practices by reducing waste and the need for additional finishing processes.

The Inner-Outer Manual Reaming Deburring Apparatus is a powerful tool that offers a range of advantages to professionals in various industries. Its versatility, precision, and durability make it an good choice for those who require high-quality deburring results. By choosing this apparatus, users can expect improved efficiency, outstanding surface finishes, and a long-term solution to their deburring needs.

English

English русский

русский Deutsch

Deutsch