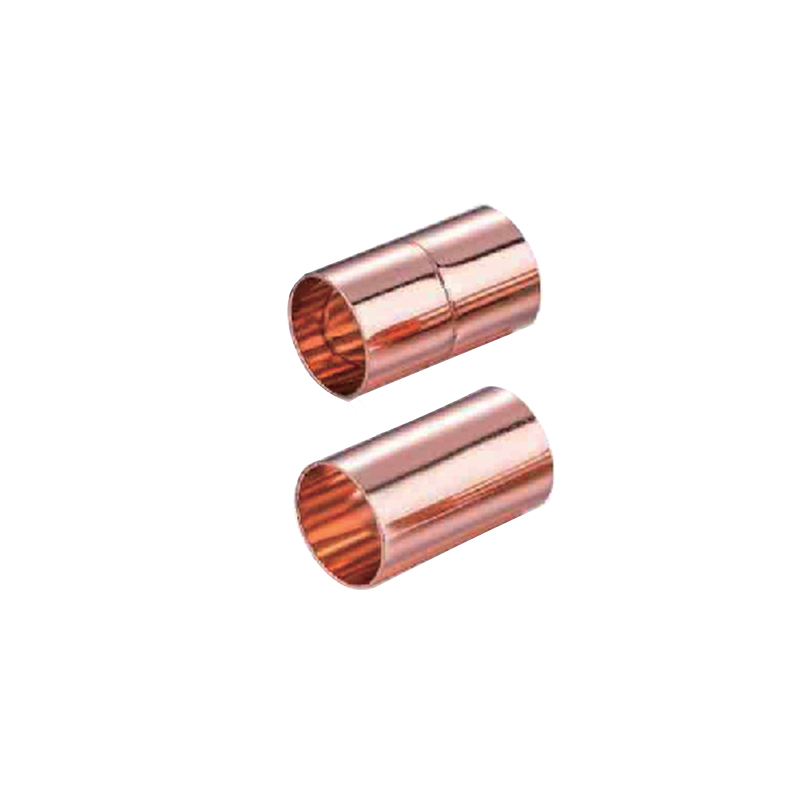

The Refrigeration Equal Coupling Copper Tube is a vital component in the field of HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration systems. This type of coupling is designed to connect two sections of copper tubing of the same diameter, ensuring a uniform and secure connection that is essential for the proper functioning of these systems. Copper is the like material for such couplings due to its good thermal conductivity, corrosion resistance, and durability.

Key Features

1. Uniformity and Compatibility: The primary function of an equal coupling is to maintain the same diameter throughout the refrigeration system. This uniformity is crucial for the efficient flow of refrigerants and the overall performance of the system.

2. Leak-Proof Connection: High-quality equal couplings are designed to create a leak-proof seal, preventing refrigerant leaks that can lead to system inefficiencies and environmental concerns.

3. Durability: Copper is known for its strength and resistance to corrosion, making it a good material for couplings that will endure the pressures and temperatures within a refrigeration system.

Types of Equal Couplings

1. Compression Fittings: These couplings use a nut and ferrule to compress the copper tube, creating a seal. They are quick to install and do not require the use of flux or solder.

2. Flare Fittings: These couplings require the tube to be flared at the end, creating a conical shape that fits into the coupling and is then secured with a nut.

3. Sweat Fittings: Sweat couplings are soldered to the copper tube, providing a strong, permanent connection. They are often used in applications where the high level of reliability is required.

Applications

Equal couplings are used in a variety of applications within the refrigeration and HVAC industry, including:

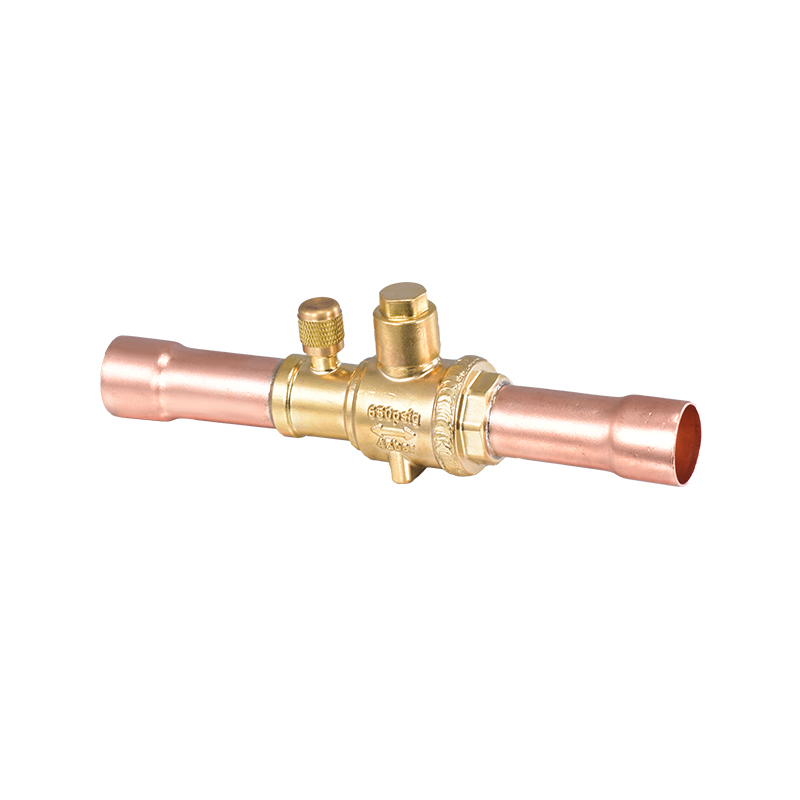

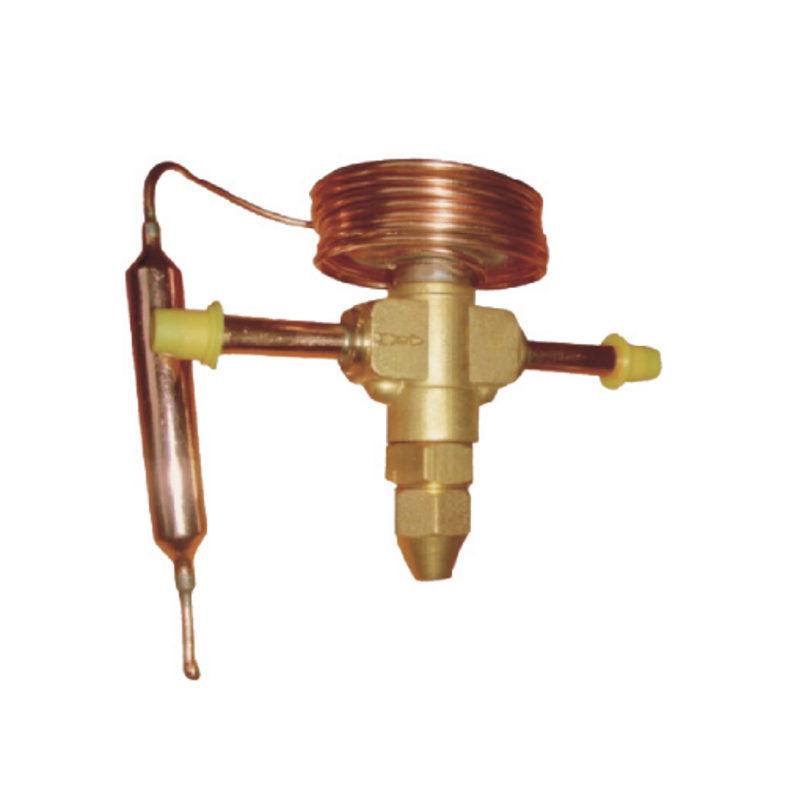

1. Residential and Commercial Air Conditioning: In both residential and commercial settings, equal couplings are used to connect the various components of air conditioning systems, such as condensers, evaporators, and expansion valves.

2. Industrial Refrigeration: In industrial settings, where large-scale cooling is required, equal couplings are essential for maintaining the integrity of the refrigeration system.

3.Automotive Air Conditioning: In automotive applications, equal couplings are used to connect the components of the vehicle's air conditioning system.

Maintenance and Troubleshooting

Proper maintenance of equal couplings is essential to prevent leaks and ensure the longevity of the refrigeration system. This includes:

1. Regular Inspections: Checking for signs of wear, corrosion, or damage to the couplings and the connected tubing.

2. Tightening: Ensuring that all fittings are properly tightened to prevent leaks. Over-tightening can cause damage, so it's important to follow the manufacturer's guidelines.

3. Replacement: If a coupling is found to be damaged or leaking, it should be replaced promptly to prevent further issues.

4. Cleaning: Keeping the couplings clean and free of debris can help prevent blockages and ensure the smooth flow of refrigerant.

The Refrigeration Equal Coupling Copper Tube is a critical component in the efficient operation of refrigeration and HVAC systems. By ensuring a uniform and secure connection between sections of copper tubing, these couplings contribute to the overall performance and reliability of the system. With proper installation, maintenance, and care, equal couplings can provide years of dependable service in a variety of applications.

English

English русский

русский Deutsch

Deutsch