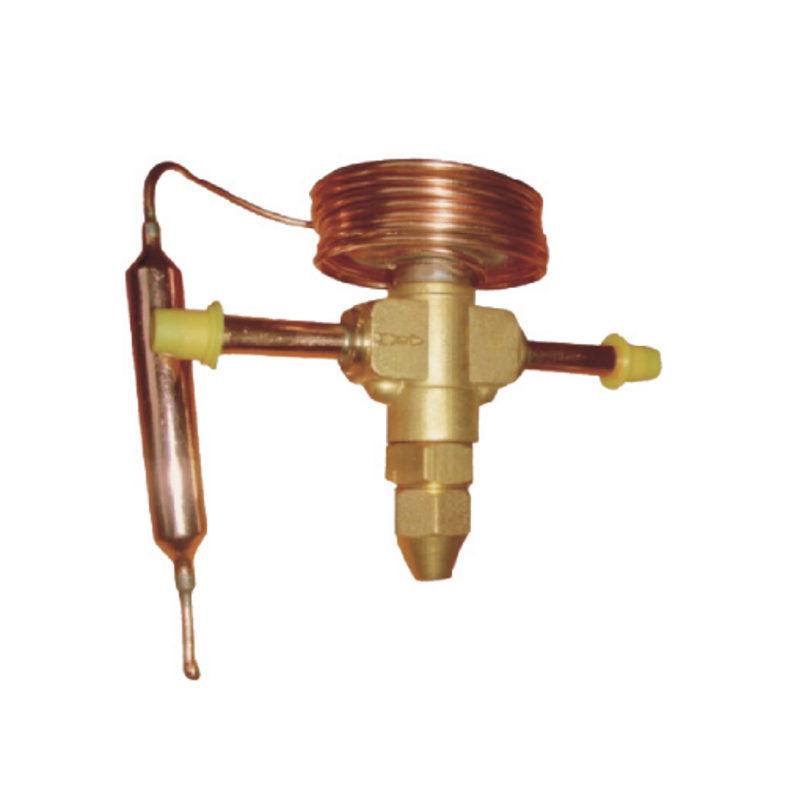

The Copper Male Adapter for Refrigeration is an essential fitting used in the HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industry. This type of adapter is designed to facilitate connections between copper pipes and various components within a refrigeration system. Made from high-quality copper, these adapters are known for their durability, corrosion resistance, and ability to withstand the pressures and temperatures associated with refrigerant flow.

Key Features and Benefits

1. Material Properties: Copper is chosen for its good thermal conductivity, which is crucial in refrigeration systems where efficient heat transfer is important. It also has high resistance to corrosion, which is beneficial in environments where moisture and chemicals are present.

2. Threaded Connections: Male adapters have external threads (male threads) that allow them to screw into female threads on other components, such as valves, compressors, or other pipes. This threading ensures a secure and leak-free connection.

3. Compatibility: These adapters are designed to be compatible with standard pipe sizes and thread types used in the industry, making them versatile for various applications.

4. Pressure Ratings: Copper male adapters are manufactured to meet specific pressure ratings, ensuring they can handle the pressures exerted by refrigerants without failure.

Applications

Copper male adapters are used in a variety of applications within the refrigeration and HVAC industry, including but not limited to:

1. Residential and Commercial Air Conditioning: In both residential and commercial settings, these adapters are used to connect copper pipes to air conditioning units, ensuring a secure and efficient transfer of refrigerant.

2. Industrial Refrigeration Systems: In larger industrial settings, such as cold storage facilities or food processing plants, copper male adapters are critical for maintaining the integrity of the refrigeration system.

3. Automotive Air Conditioning: In automotive applications, these adapters are used to connect the various components of the vehicle's air conditioning system, ensuring efficient cooling.

4. Heat Pump Systems: Heat pumps rely on the transfer of refrigerant to move heat from one place to another. Copper male adapters are used to connect the components that facilitate this process.

Installation and Maintenance

When installing a copper male adapter, it is important to follow these steps to ensure a proper and secure connection:

1. Cleanliness: Ensure that both the adapter and the component it is connecting to are clean and free of debris. This prevents any particles from interfering with the thread engagement.

2. Thread Lubrication: Apply a suitable thread lubricant, such as pipe joint compound or Teflon tape, to the threads of the male adapter. This helps to create a leak-free seal and makes the connection easier to tighten.

3. Tightening: Hand-tighten the adapter first, then use a wrench to tighten it to the manufacturer's specified torque. Over-tightening can cause the threads to strip or the fitting to crack.

4. Leak Checking: After installation, it is crucial to check for leaks using a refrigerant leak detector or by applying a soapy water solution to the connection. Any bubbles indicate a leak that needs to be addressed.

The Copper Male Adapter for Refrigeration is a small but vital component in the complex systems that keep our environments comfortable and our food fresh. Its durability, compatibility, and ease of use make it a like choice for professionals in the HVAC and refrigeration industry. By understanding the importance of these adapters and following proper installation and maintenance practices, technicians can ensure the longevity and efficiency of the systems they service.

English

English русский

русский Deutsch

Deutsch